Master Builders Solutions: Project Atlas

Empowering concrete producers with real-time data

Project Atlas was a product innovation effort aimed at providing ready mix producers with the real-time data and actionable insights needed to maintain the highest-quality concrete from plant to job site.

Setting Context

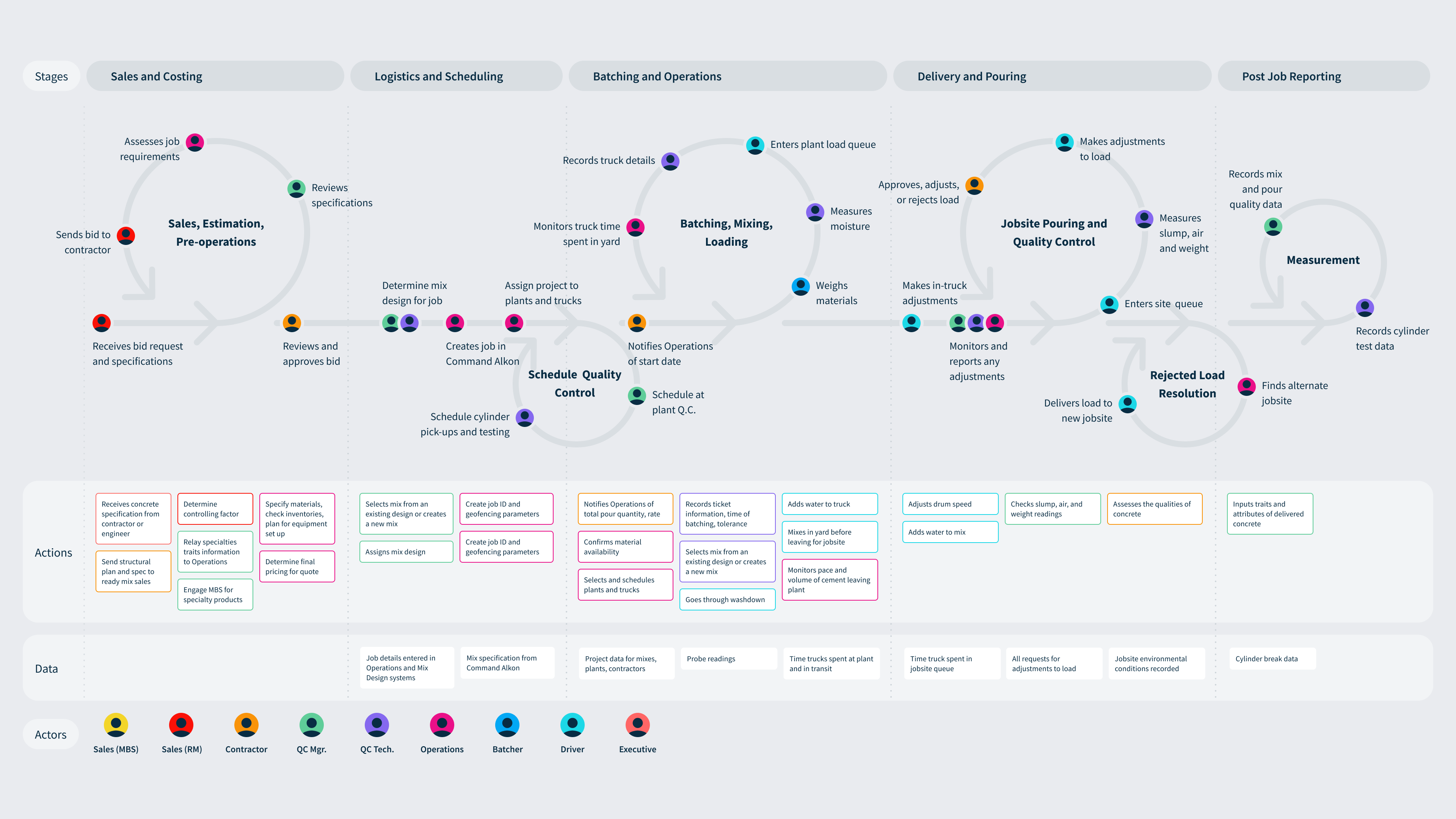

To gain a comprehensive understanding of the end-to-end process, all touchpoints, from the initial job estimation phase through post-delivery operations were explored. This provided played a pivotal role in pinpointing the areas that required the most attention.

Mapping Touchpoints

The entire journey, spanning job estimation to post-delivery operations, was documented. The touchpoint map provided a clear visualization of stakeholder roles and responsibilities throughout the product lifecycle, enabling the team to pinpoint process gaps and areas in need of improvement.

Defining the Project Focus

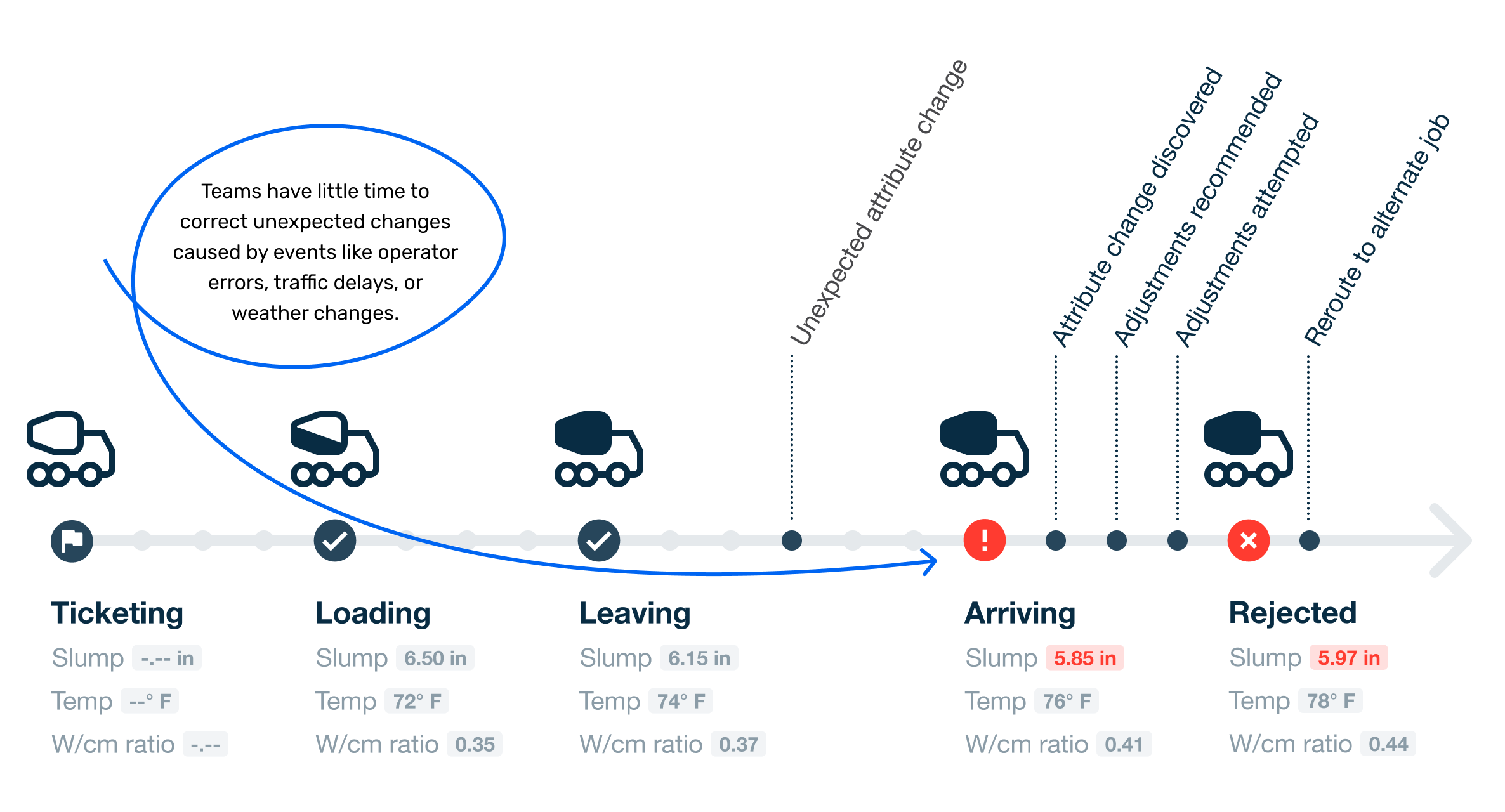

These sessions prioritized the need to address the challenges associated with maintaining predictable concrete loads during the critical journey from the plant to the job site.

Identifying a Secondary Opportunity

In addition to the main goal, the project had a secondary focus, collecting batch data to optimize future mix designs.

Exploring Key Problem Areas

Through in-depth interviews with ready-mix producers, dispatchers, and quality control personnel, three critical areas, plagued with recurring pain points and gaps, were identified.

Lack of Real-time Data

Concrete producers are tasked with managing a multitude of variables, such as material availability, environmental conditions, and travel times. However, they lack access to real-time data, hindering their ability to make informed decisions and respond promptly to changing circumstances.

Inefficient Communication Channels

Communication between different disciplines and team members often suffers from inefficiencies, leading to miscommunications, delays, cost overruns, and even rejected concrete. Enhancing communication channels emerged as an area for improvement.

Quality Control Challenges

Quality control personnel face increasing complexity in adhering to stringent specifications and sustainability requirements. This challenge demands close attention to detail to ensure consistent quality while maintaining profitability.

Addressing Pain Points

Integrating real-time data from sensors (at plants, in trucks, and on jobsites) into a single platform empowers team members in critical decision-making moments to assure the integrity of delivered concrete.

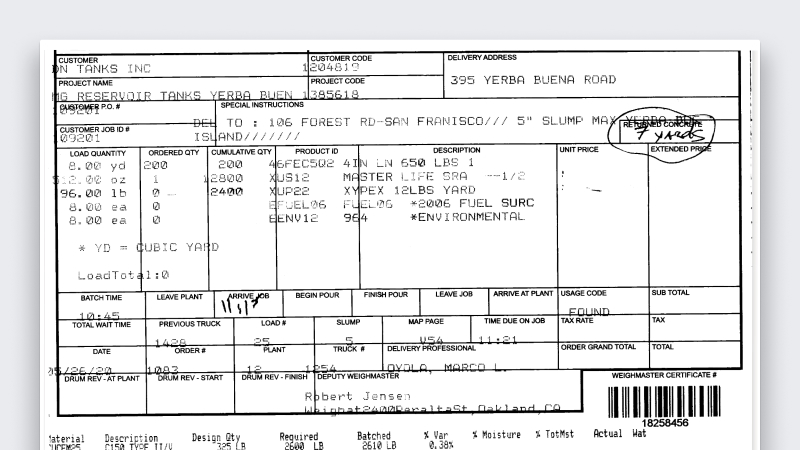

Which Data Today? Tomorrow?

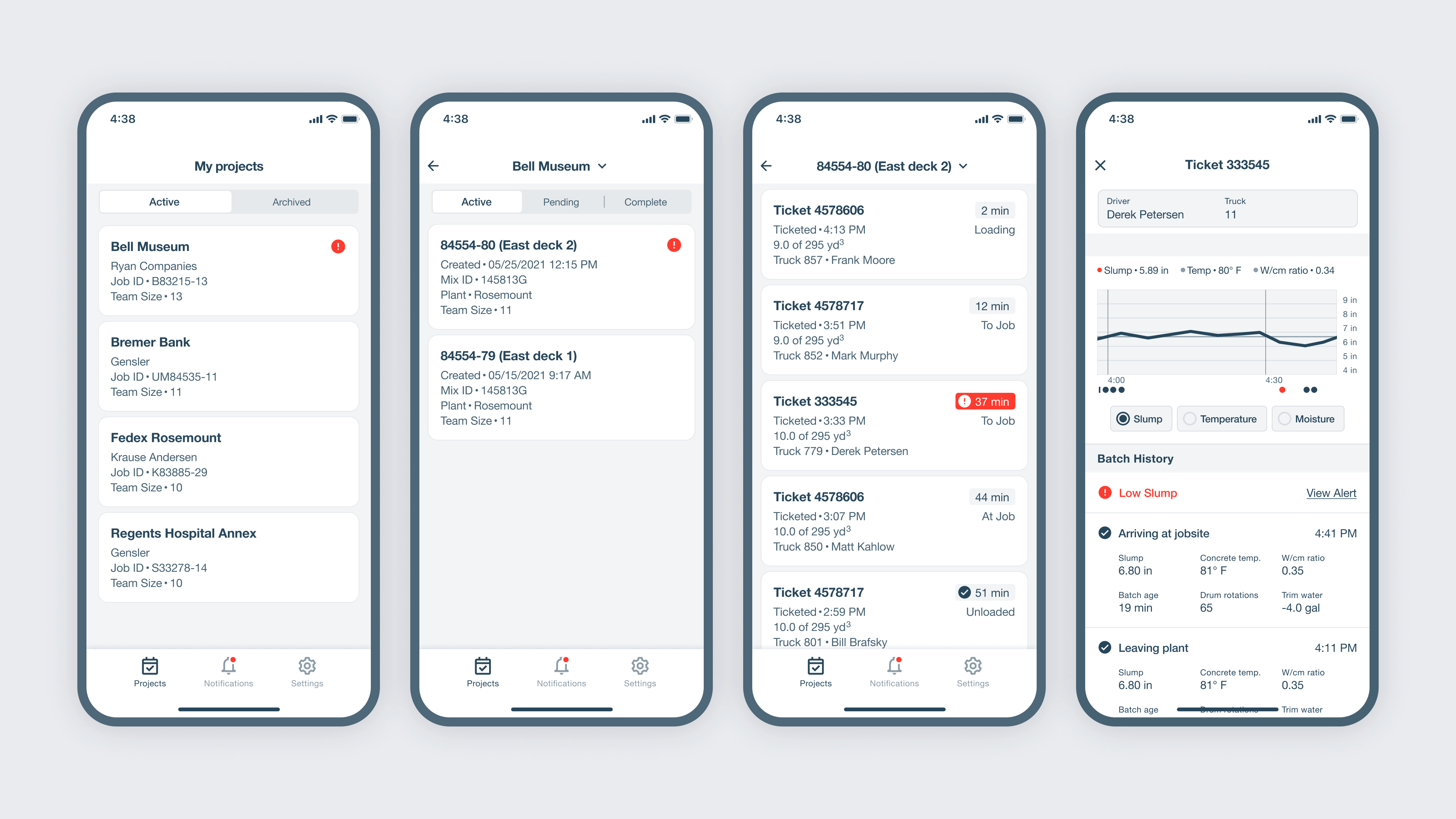

Quality control managers identified the details they use in traditional paper tickets and which ones they would require for tracking batch quality from plant to job site.

To make informed decisions, QC personnel in the field required access to multi-faceted live data and insights spanning various levels, from job IDs down to point-in-time measurements of individual tickets.

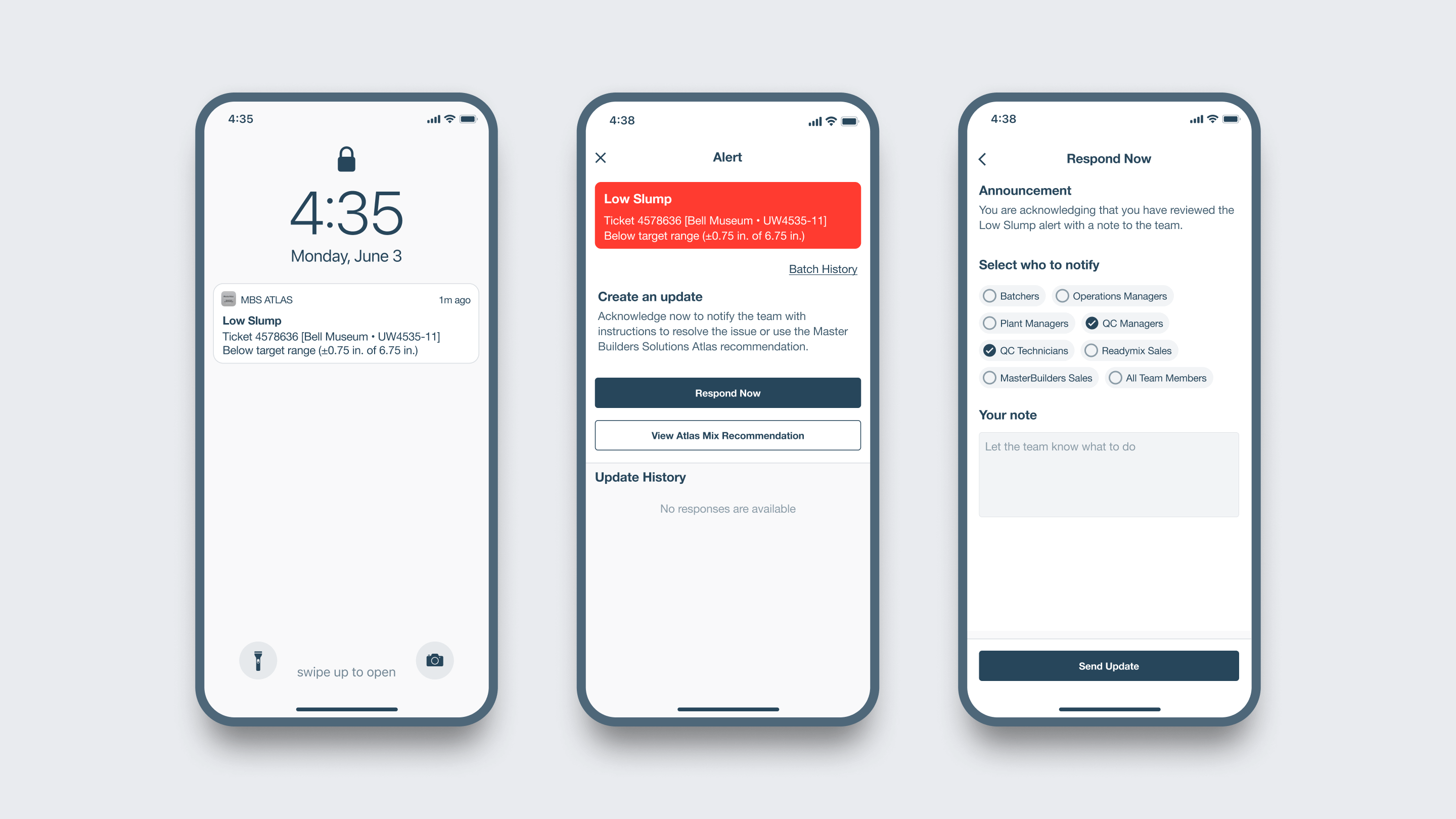

By notifying the right people at the right time when an outlier is detected, decision-makers have time to analyze the situation, identify the cause, and take action to resolve the issue.

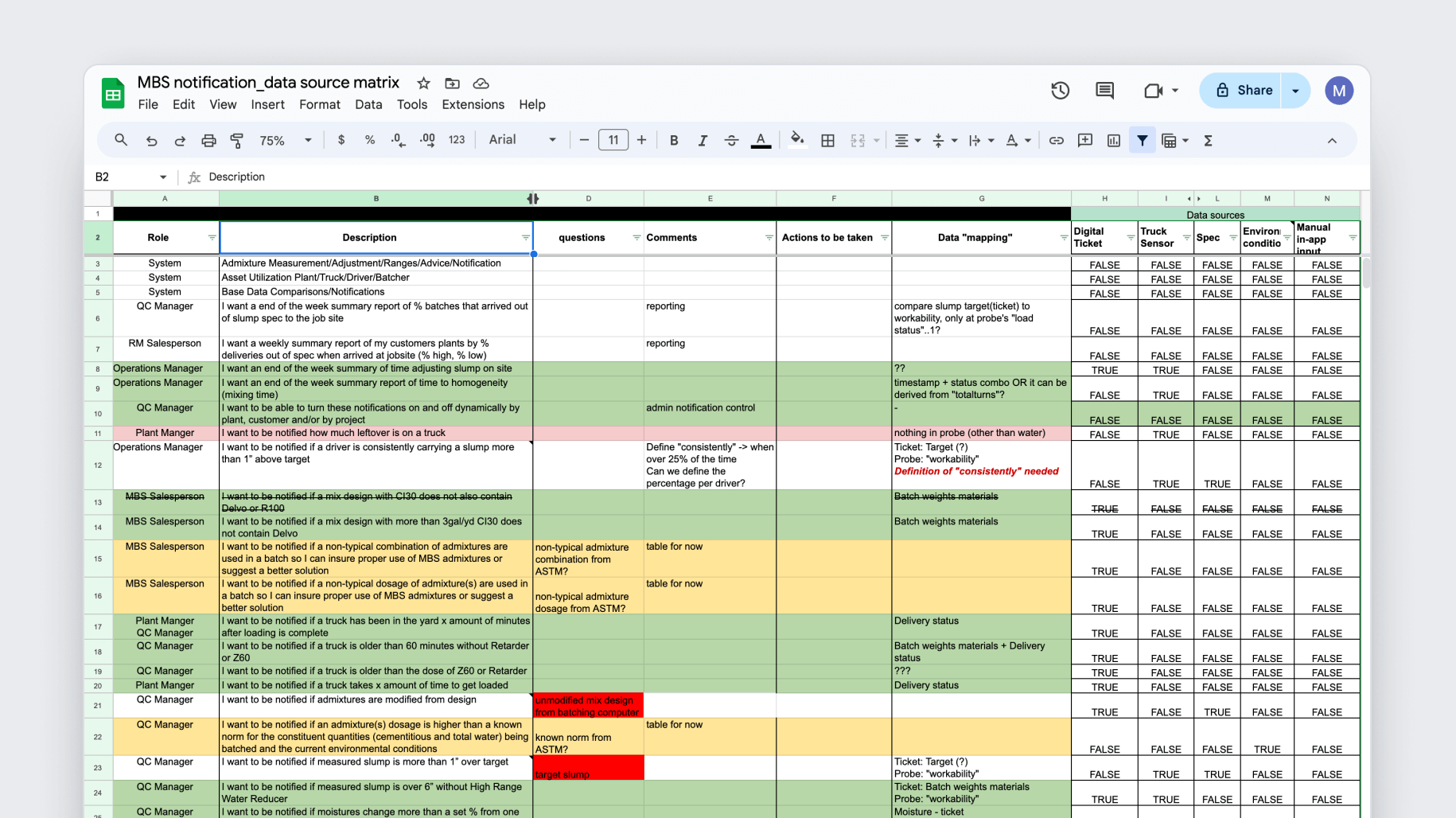

Defining Timely and Actionable Insights

Working with operations and materials experts, I documented a matrixed system of material data, team roles, risks to concrete quality, and corrective interventions. This information was then evaluated by data analysts and engineers to ensure that the system architecture would deliver the appropriate updates to the right team members at the right times, assuring the delivery of the highest quality concrete to the job site.

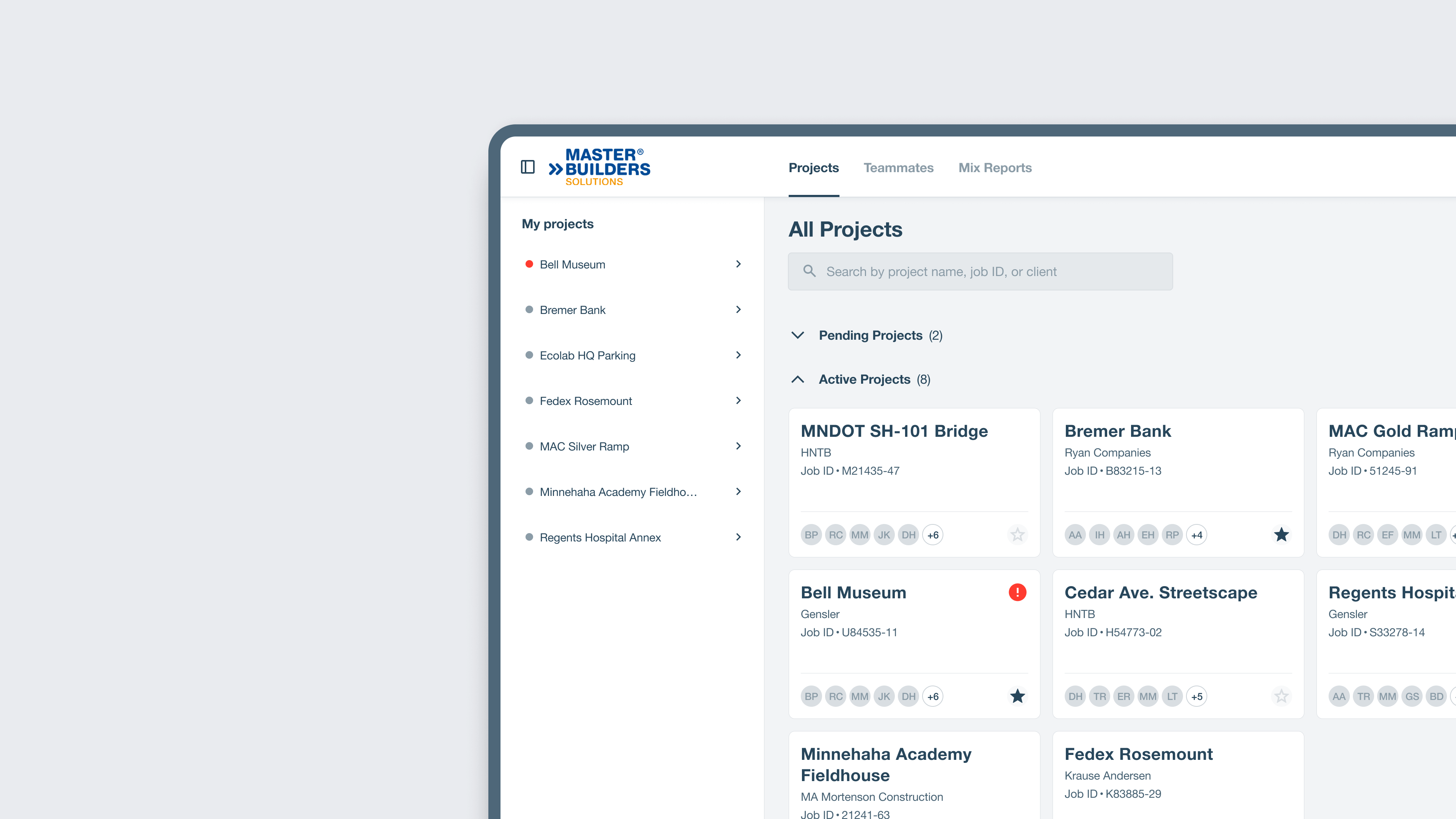

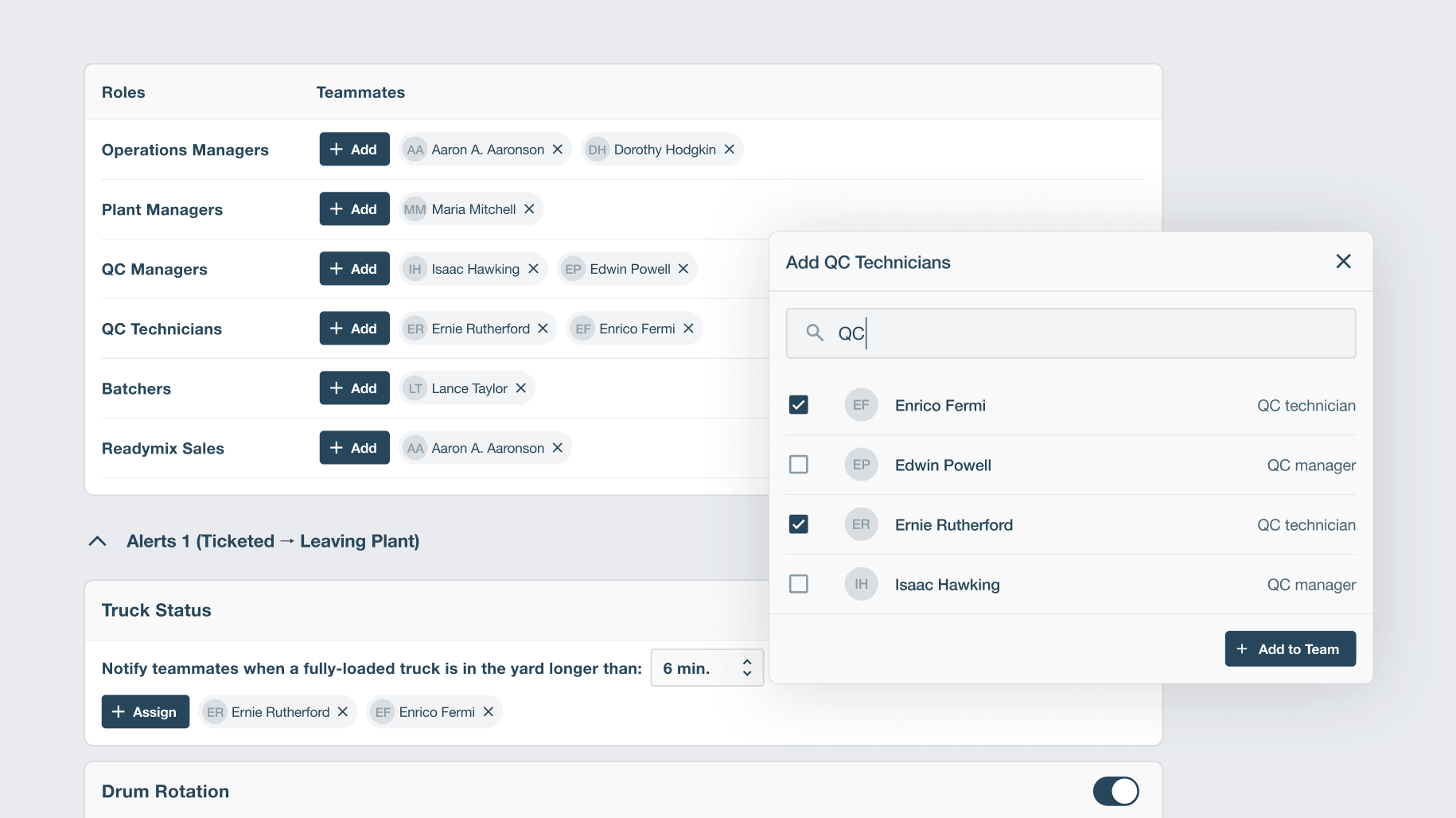

Assembling the Right Team

Early concept tests provided insights showing that no single solution would be appropriate for delivering pertinent information to the right person in every scenario. Due to this, we equipped operations managers with tools to configure teams and alerts on a project-by-project basis. This approach ensures a solution capable of aligning with each project's unique requirements.

The system serves as extra set of eyes and ears for the entire team in the field by watching for issues, surfacing warnings, and providing updates as they occur.

Mobile Notification System

When an out-of-range material parameter is detected, comprehensive alerts detailing the issue and preceding events are promptly pushed to qualified team members empowered to take action. Their subsequent actions then trigger notifications informing the team of the necessary steps to be taken.

Capturing better project and batch data helps to ensure future projects face fewer risks to material quality while maximizing margins.

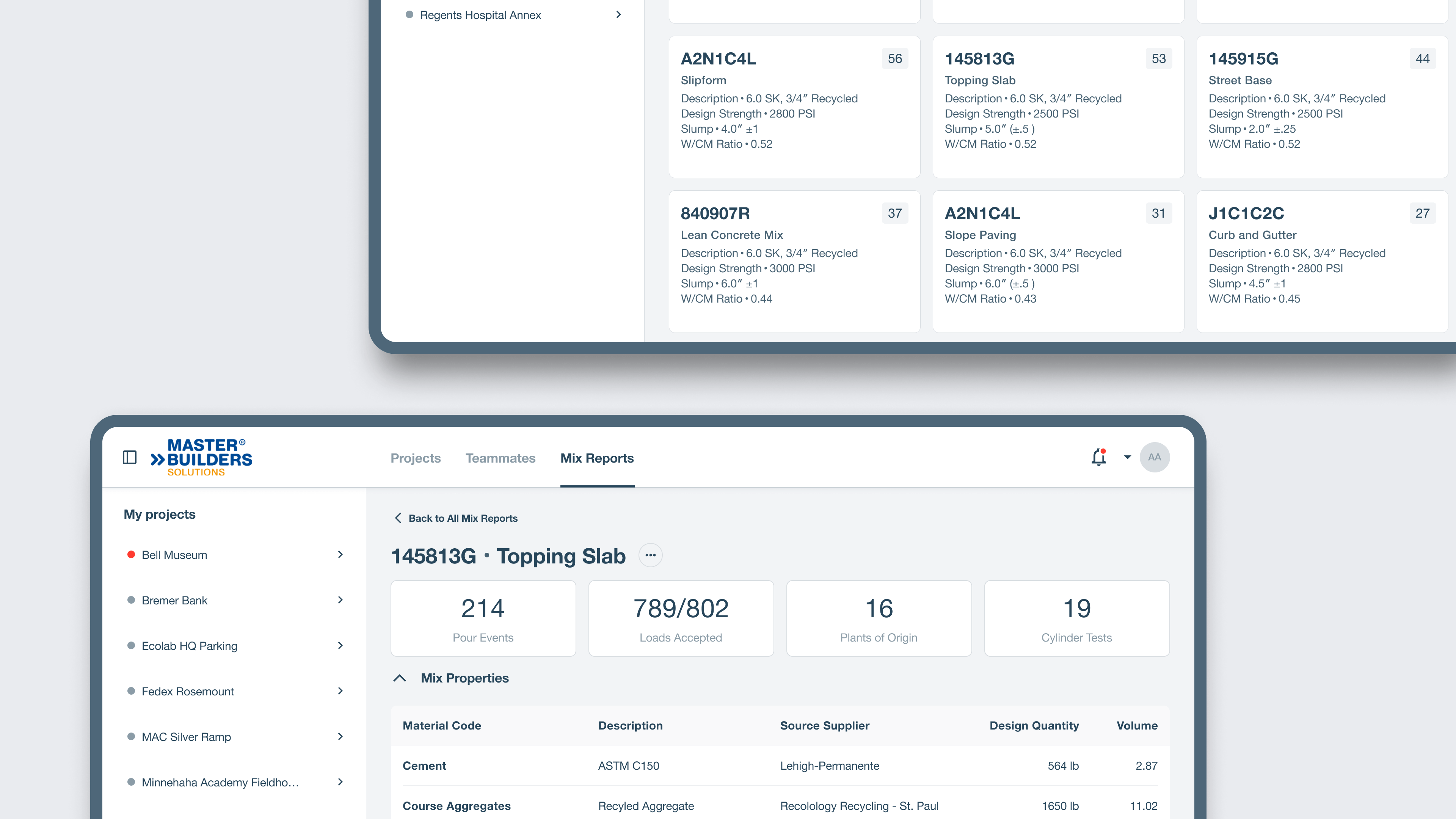

Optimizing for Future Jobs

Using data collected from our new tracking system, we designed the administrator portal to seamlessly consolidate delivery histories with a library of mix specifications. This empowers ready mix producers with the ability to see implementation track records for each of their mix designs. This integrated approach enables proactive measures to be taken, leveraging historical data and insights to improve outcomes in future jobs.

Outputs and Outcomes

Testing provided confidence to deliver a first generation product to Master Builders Solutions’ clients via native mobile (iOS & Android) apps and a desktop management portal.

Simple and Intuitive Interfaces

With a focus on intuitive usability, the experience was designed to require minimal training, making it accessible to all team members, regardless of their level of technical knowledge.

Personalized Experiences

Designed to address the specific needs of each user, ensuring they have access to the information and insights they need, when they need it. All team members are empowered to seamlessly engage and contribute to problem resolutions, creating a more efficient and cost-effective end-to-end process.

A Roadmap for Future Iterations

Next generation features were designed to integrate additional IoT data sources like on-site weather sensors to maximize the effectiveness of Master Builders Solutions' predictive AI product.